- You are here:

- Machinery

Machinery

We currently use brand new Borche machinery to produce injection-molded plastic parts.

Our moulding capabilities range from 200 to 2200 ton 2K technology.

List of injection molding machines

| Press | Name | Closing force (tons) | Screw diameter (mm) | Min. tool height (mm) | Max. tool height (mm) | Turning table (2K) |

|---|---|---|---|---|---|---|

| AE-01 | Borche Bi200 | 200 | ø50 | 180 | 550 | |

| AE-02 | Borche BS200 | 200 | ø50 | 180 | 550 | |

| AE-03 | Borche BS320 | 320 | ø70 | 220 | 655 | |

| AE-04 | Borche BS320 | 320 | ø70 | 220 | 655 | |

| AE-05 | Borche BU600 | 600 | ø85 | 300 | 870 | |

| AE-06 | Borche BM500-150ML | 500 | ø80 / ø45 | 475 | 1100 | 3t |

| AE-07 | Borche BU1500 | 1500 | ø130 | 700 | 1400 | |

| AE-08 | Borche BM2200-320ML | 2200 | ø160 / ø70 | 800 | 1700 | 15t |

Types of injection molding machines used

We currently use these types of Borche injection molding machines for the production of plastic parts:

Borche Bi

The Bi series is able to connect peripherals and implement two-way data communication that integrates peripheral information into the machine's control unit. The Bi series can be connected to PC or mobile phone. The user can easily monitor the condition of the machines using connectivity and built-in sensors.

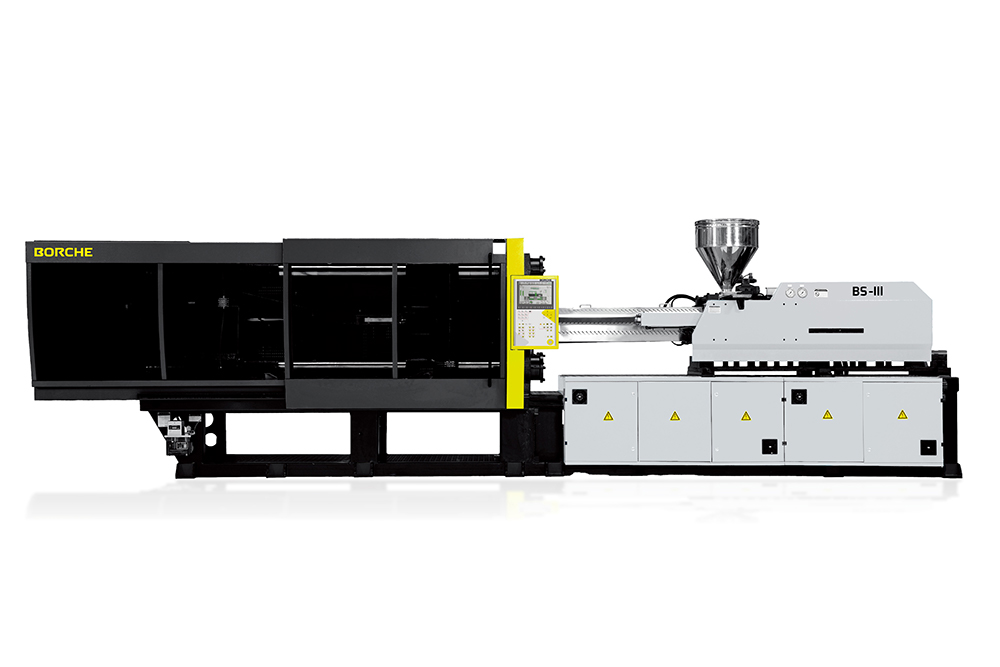

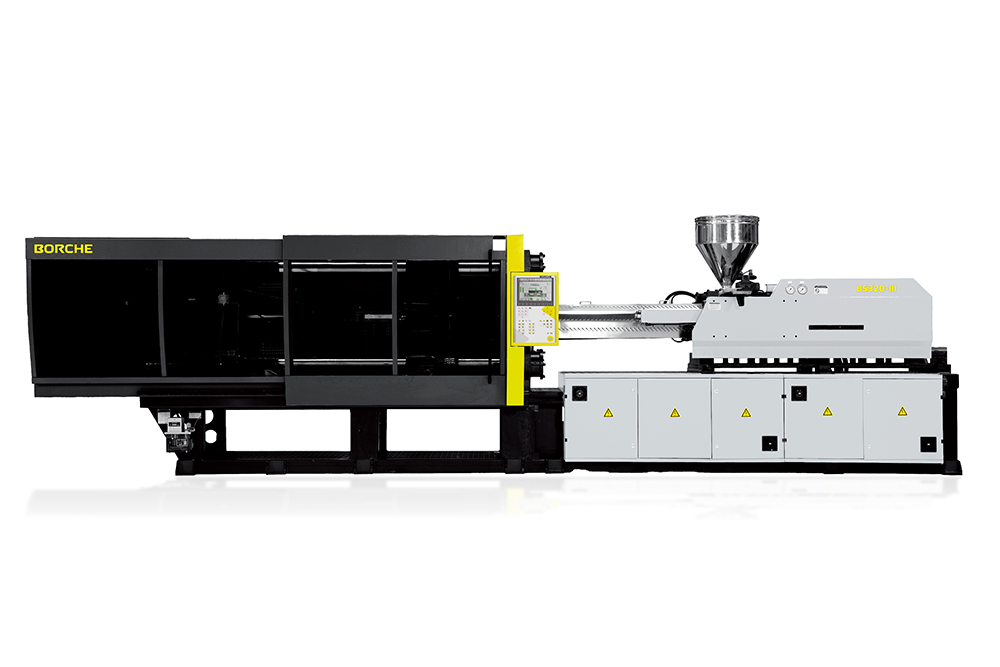

Borche BS III

The BS-Ill Servo series is equipped with an adequate power supply system, high-precision control, stable performance, high versatility and three chamber sizes, which can meet a variety of production requirements.

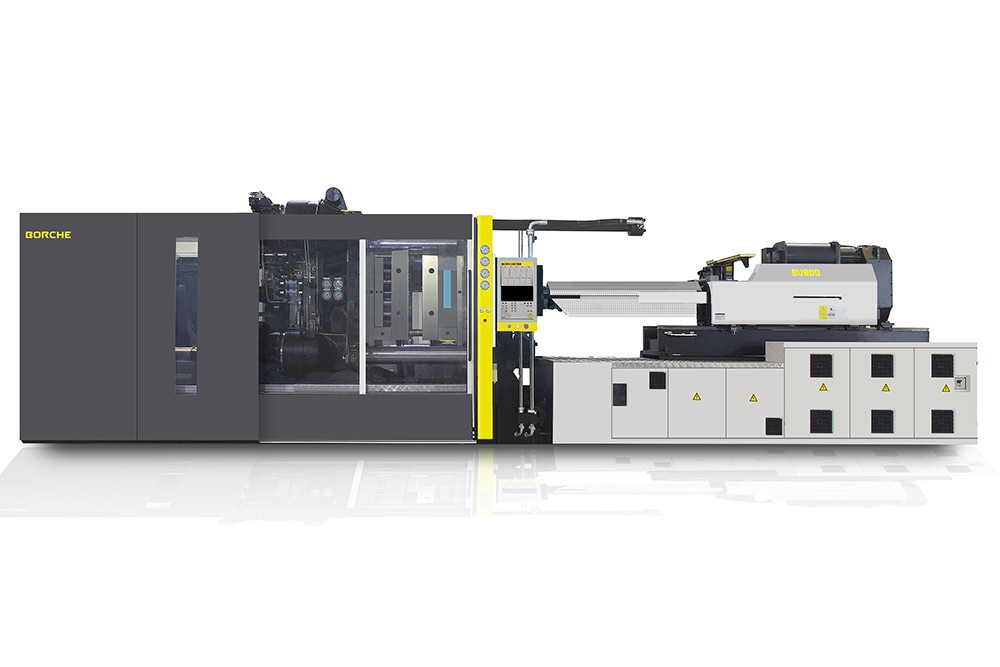

Borche BM

The BM series multi-component machines provide stable, accurate and flexible solutions for a wide variety of production requirements. With many years of experience in this category, we can implement multi-component 2K injection molding in one production process on a given machine.

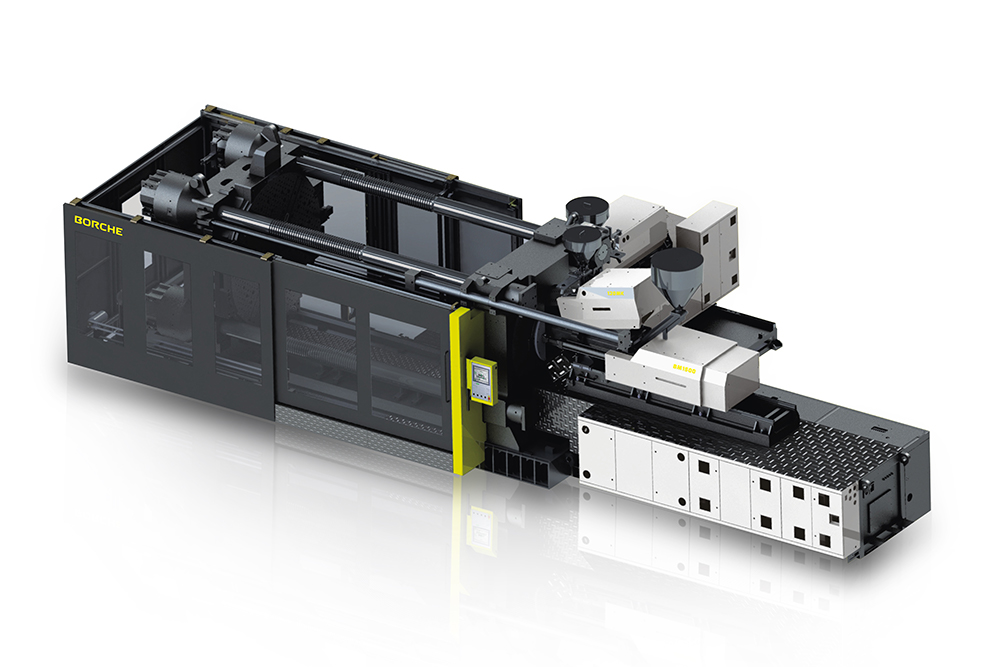

Borche BU

The BU series two-plate injection molding machines are most often used for the production of parts and components for the aerospace, automotive, transportation and construction industries. The IMM interface enables intelligent connection of operators, peripherals and robots. All devices are thus under control with constant data mapping, which ensures the optimization of production costs.